One of the standard services of the Institute for Chemical Processing of Coal (IChPW) – Department of Cokemaking Technologies is the normalization of hydraulic and temperature parameters of coke oven batteries, which allows to achieve and maintain optimal operation parameters, from the point of view of the quality of coking products, durability of the construction, reduction of energy consumption of the process and emission of pollutants to the environment.

The detailed scope of works performed during the standardization process has been discussed in the article (http://www.itpe.pl/blog/2022/02/14/ocena-stanu-baterii-koksowniczej-regulacja-parametrow-hydrauliczno-temperaturowych-baterii-koksowniczych/ ). In this paper – based on the experience from the regulatory works carried out by ICHPW on currently exploited batteries – the achieved economic effects of these works have been presented.

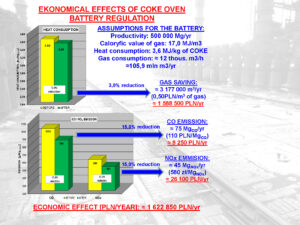

The results of the regulatory works on batteries of various constructions and different productivities – in order to more conveniently refer to other batteries – were averaged and presented for a coke oven battery with a productivity of 500 thousand Mg of coke per year. The initial technological parameters of the coke oven battery and the results obtained have been presented in the diagram below (Fig. 1), assuming that these values will be maintained for one year of battery exploitation, under unchanged operating conditions. The minimum level of PLN 0.5/m3 of coke oven gas unit price has been adopted here, which currently ranges from ?0.5÷1.0 PLN/m3 of gas.

The results of the regulatory works on batteries of various constructions and different productivities – in order to more conveniently refer to other batteries – were averaged and presented for a coke oven battery with a productivity of 500 thousand Mg of coke per year. The initial technological parameters of the coke oven battery and the results obtained have been presented in the diagram below (Fig. 1), assuming that these values will be maintained for one year of battery exploitation, under unchanged operating conditions. The minimum level of PLN 0.5/m3 of coke oven gas unit price has been adopted here, which currently ranges from ?0.5÷1.0 PLN/m3 of gas.

The above data are similar to the levels obtained on medium exploited coke oven batteries with good technical condition. For significantly exploited coke oven batteries, their energy and operational parameters are usually much worse, and thus the subsequent positive effects of the regulation are much more favorable (even several times !!!).

Conducting a thorough normalization of hydraulic and temperature parameters of the heating system of each coke oven battery always brings positive operational and economic effects. Particularly visible effects of these works can be noted on significantly exploited batteries. As an example is here the coke oven battery with charging system No. 11 (chamber dimensions 16.0 x 7.0 x 0.41 m.) located at the Liberty Ostrava a.s. in the Czech Republic. The battery, thanks to the systematic (every 2÷3 years) normalization activities undertaken by IChPW, in combination with appropriate preventive and repair works, is characterized by stable operation for over 40 years (since October 1981), despite the obvious signs of its exploitation.

The Institute for Chemical Processing of Coal – Department of Cokemaking Technologies encourages to wide cooperation all interested Coke Plants, which will certainly bring, apart from improving the quality of coke oven battery operation, also measurable economic benefits. IT JUST PAYS OFF.

Author: Grzegorz Nowicki

Department of Cokemaking Technologies

contact: gnowicki@itpe.pl